Premium-Grade Aluminum Castings: Key Applications and Benefits

High-strength aluminum castings are gaining recognition for their wide-ranging applications and substantial benefits throughout various industries. Their low weight and resistance to corrosion render them especially useful in sectors including automotive and aerospace. Nevertheless, the advantages go beyond merely performance. As developments in alloy compositions and casting processes progress, the possibility for these materials to revolutionize engineering solutions increases. This triggers an examination of how these progressions will shape future applications and industry norms.

Primary Advantages of High-Strength Aluminum Castings in Diverse Industries

Superior aluminum castings offer many benefits across multiple industries, boosting performance and efficiency. One key benefit is their minimal weight features, which lowers overall product weight without reducing strength. This attribute is critically vital in fields such as aerospace and automotive, where weight reduction results in improved fuel efficiency and operational performance.

Additionally, high-strength aluminum castings demonstrate outstanding corrosion resistance, which makes them well-suited for applications in challenging environments. This durability extends the lifespan of components, minimizing maintenance costs and downtime.

Furthermore, the adaptability in design permits complex geometries that can generate innovative product designs, promoting creative and functional solutions.

High-strength aluminum castings also provide superior thermal conductivity, which is advantageous in applications demanding effective heat dissipation. These unified attributes establish high-strength aluminum castings as a preferred choice for manufacturers aiming to realize high performance and longevity in their products.

Practical Uses of High-Strength Aluminum Castings

The lightweight and durable characteristics of aluminum castings make them extremely desirable in various applications across several industries. In the automotive sector, strong aluminum castings are implemented for engine blocks, transmission housings, and structural components, enhancing fuel efficiency and performance. Aerospace manufacturers implement these castings for aircraft components, offering the necessary strength while reducing overall weight, thus increasing fuel economy and payload capacity.

Moreover, the construction industry employs high-strength aluminum castings for architectural features and structural supports, providing durability and aesthetic appeal. In the marine sector, these castings are critical for boat hulls and engine parts, guaranteeing resistance to corrosion and weight optimization. Additionally, consumer electronics manufacturers employ aluminum castings for enclosures and frames, integrating strength and lightweight properties to enhance product design. Overall, the versatility of high-strength aluminum castings facilitates innovation across multiple fields, driving progress in design and functionality.

Leading Industries Employing High-Strength Aluminum Castings

As industries seek to enhance performance and reduce weight, high-strength aluminum castings have proven to be an essential material in various sectors. The automotive industry is a key player, utilizing these castings for engine components, structural parts, and chassis to enhance fuel efficiency and reduce emissions. Additionally, aerospace manufacturers are increasingly adopting high-strength aluminum castings for aircraft components, benefiting from their strength-to-weight ratio, which supports overall aircraft performance and safety.

The nautical field also employs these castings for durable yet lightweight components, enhancing vessel speed and efficiency. In the industrial machinery sector, manufacturers utilize high-strength aluminum castings for components that require high durability while preserving a light profile. Finally, the electronics industry uses these castings for housing and structural elements, merging aesthetics with functionality. In summary, high-strength aluminum castings are transforming multiple industries by offering innovative solutions that satisfy modern demands for performance and efficiency.

Optimizing Performance Using High-Strength Aluminum Castings

Industrial-strength aluminum castings provide considerable advantages in performance enhancement across numerous applications. Their weight reduction capabilities result in improved efficiency, while superior durability features provide longevity and reliability. Moreover, the design flexibility they offer allows for innovative solutions adapted to specific industry needs.

Weight Loss Benefits

While various industries search for strategies to elevate performance, mass reduction through high-strength aluminum castings proves to be an essential tactic. Aluminum's inherent lightness facilitates meaningful reductions in component mass without compromising structural integrity. This minimization supports superior fuel efficiency in transportation and aviation sectors, resulting in decreased operating expenses and minimized emissions. In addition, reduced-weight parts allow for quicker acceleration and improved handling, which constitute vital aspects in competitive markets. Moreover, the flexibility in design offered by aluminum castings allows for complex geometries that continue to reduce mass without compromising capability. Consequently, companies leveraging high-strength aluminum castings can achieve substantial advantages in capability, efficiency, and comprehensive product excellence, making it a preferred choice in modern manufacturing.

Enhanced Longevity Features

Though various materials provide strength, high-strength aluminum castings offer outstanding durability that boosts the performance of various applications. These castings show superior resistance to wear, corrosion, and impact, making them excellent for demanding environments. The natural properties of aluminum, combined with advanced casting techniques, result in components that preserve structural integrity under extreme conditions. This durability not only lengthens the lifespan of products but also lowers maintenance costs, enhancing overall efficiency. Industries such as automotive, aerospace, and industrial machinery profit substantially from these characteristics, as they require materials that can withstand demanding operational demands. Finally, the enhanced durability of high-strength aluminum castings positions them as a reliable choice for high-performance applications across multiple sectors.

Design Versatility Options

The adaptable nature of aluminum castings permits for remarkable design flexibility, allowing engineers and designers to produce complex geometries that fulfill specific performance requirements. This adaptability supports the integration of features such as sophisticated internal cooling channels or lightweight lattice structures, optimizing functionality without compromising strength. High-strength aluminum castings also enable rapid prototyping, allowing for iterative design processes that enhance innovation. The material's excellent machinability further permits post-casting modifications, such as machining or surface treatments, to reach desired finishes and tolerances. Finally, this design flexibility results in improved performance in diverse applications, from aerospace components to automotive parts, making certain that products are learn now not only efficient but also adapted to address the evolving demands of modern engineering challenges.

Progressive Solutions Powering Performance in Aluminum Castings

Many innovations are changing the landscape of aluminum castings, considerably improving their performance and applications across diverse industries. Advanced alloy compositions, for instance the introduction of lithium and magnesium, are boosting strength-to-weight ratios, making castings lighter yet stronger. At the same time, the adoption of sophisticated casting techniques, including 3D printing and vacuum casting, facilitates intricate designs and reduced waste, enhancing production efficiency.

Moreover, progress in heat treatment processes are enabling manufacturers to obtain excellent mechanical properties, enhancing the durability of aluminum castings under extreme conditions. The implementation of smart manufacturing technologies, such as real-time monitoring and artificial intelligence, additionally enhances quality control, providing consistency and precision throughout the casting process. These innovations jointly facilitate a varied range of applications, from automotive components to aerospace structures, illustrating the increasing demand for high-performance materials in an progressively competitive marketplace.

High-Strength Aluminum Castings vs Other Material Options

How can high-strength aluminum castings compare to conventional materials like steel and plastic regarding performance and application? High-strength aluminum castings provide a distinctive blend of qualities that position them as a competitive alternative. They are considerably lighter than steel, which can lead to enhanced fuel efficiency in automotive and aerospace applications. While steel excels in tensile strength, aluminum castings provide sufficient strength with the advantage of lower weight, making them ideal for various structural applications.

Conversely, plastic materials, while often lighter and resistant to corrosion, don't have the thermal and mechanical properties required for high-stress environments. Aluminum castings also display enhanced thermal conductivity than both steel and plastic, improving their performance in applications that require heat dissipation. In summary, high-strength aluminum castings close the gap between the robustness of steel and the versatility of plastics, making them an increasingly popular choice in various industries.

What Lies Ahead for Aluminum Casting Technological Advances?

What developments are on the horizon for aluminum casting technologies? Industry experts anticipate major advancements propelled by automation, advanced materials, and better processes. One hopeful domain includes the integration of artificial intelligence in the manufacturing and design operations, permitting more efficient mold design and defect detection. Furthermore, progress in 3D printing technology are anticipated to transform the creation of complex geometries, minimizing material waste and lead times.

Moreover, researchers are examining new aluminum alloys that deliver superior strength-to-weight ratios and corrosion resistance, broadening potential applications in aerospace and automotive sectors. The development of sustainable practices, such as recycling aluminum scrap and reducing energy consumption during casting, is also becoming increasingly important. These advancements will not only enhance the performance of aluminum castings but also promote environmentally responsible manufacturing. As these technologies advance, they are poised to redefine the landscape of aluminum casting, making it more efficient and versatile than ever before.

Questions & Answers

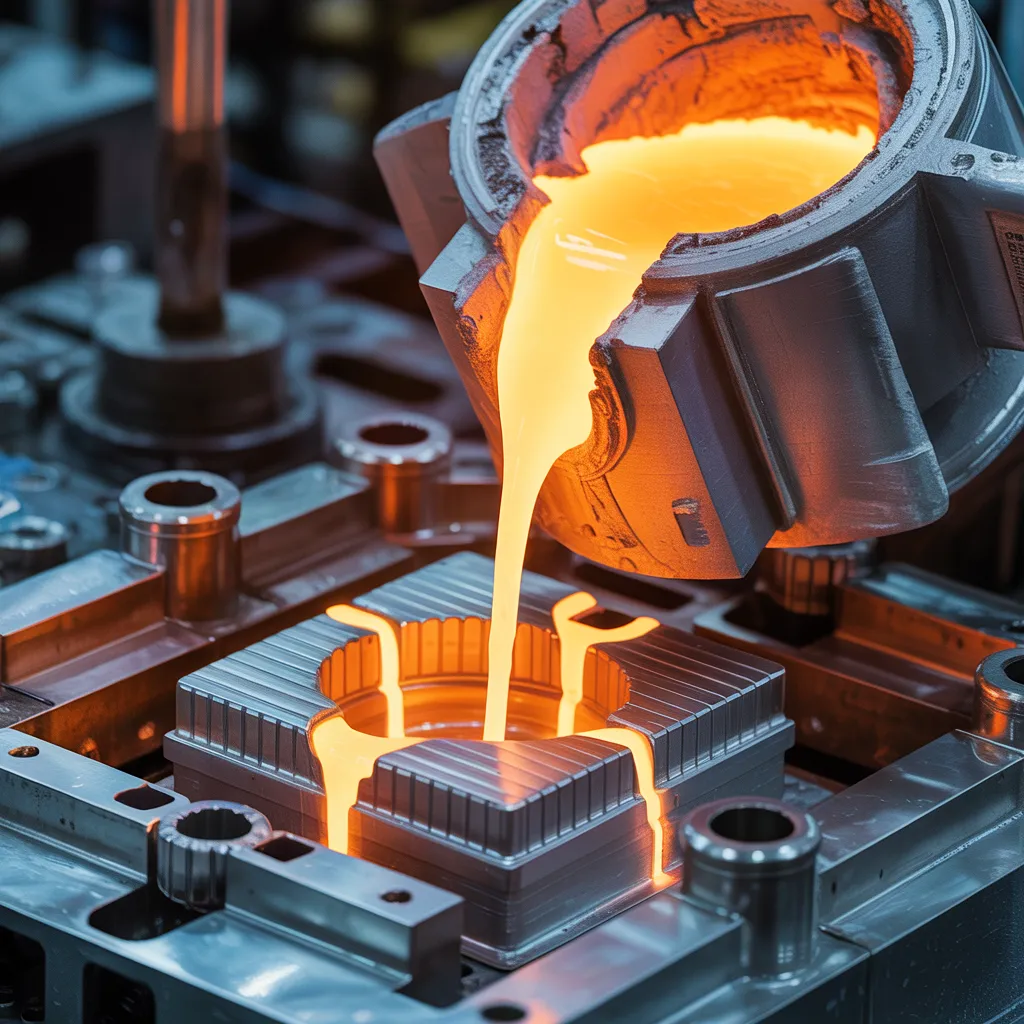

How Are High-Strength Aluminum Castings Produced?

High-quality aluminum castings are created through procedures like sand casting, die casting, or investment casting. These approaches involve heating aluminum alloys, dispensing them into molds, and allowing them to solidify, yielding long-lasting and lightweight components.

What Is the Environmental Impact of Aluminum Casting Processes?

The ecological effects of aluminum casting operations encompass energy consumption, greenhouse gas emissions, and waste generation. Effective management practices and recycling programs can reduce these impacts, promoting sustainability in aluminum production and lowering its environmental impact.

Can You Recycle High-Strength Aluminum Castings?

Indeed, high-strength aluminum castings can be recycled. The recyclable nature contributes to environmental sustainability, enabling manufacturers to recover and repurpose materials, reducing waste and energy consumption while fostering a circular economy in the aluminum sector.

How Do Manufacturing Expenses Compare to Other Material Options?

Production expenses for high-strength aluminum castings are usually higher than conventional materials like steel but lower than titanium. Their lightweight attributes and corrosion resistance can balance out initial expenses through lower operational costs in specific applications.

How Long Do High-Strength Aluminum Castings Typically Last?

The expected lifespan of high-strength aluminum castings varies between 10 to 20 years, contingent upon environmental factors and maintenance. Their robust nature and resistance to corrosion make a significant contribution to their longevity in multiple applications.